Typical Tensile Strength of Materials

Table of Contents

Ultimate Tensile Strength?

The ultimate tensile strength of a material is the maximum stress that it can withstand and resist tearing due to tension. This is an important material property used in the design of beams, vehicles and in other engineering industries.

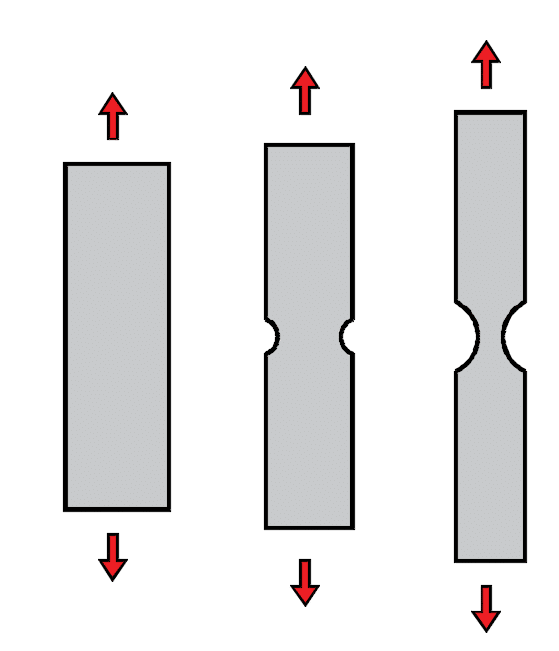

The ultimate tensile strength is found through experimental data on specimens. A steel rod is placed in a tensile testing machine (universal testing machine), which involves applying a tensile stress to the metal rod. The metal rod is held by 2 clamps (top and bottom), with an applied tensile load at one end. The strain in the rod is recorded against the applied stress at each instance until failure, and this is recorded as a stress strain graph.

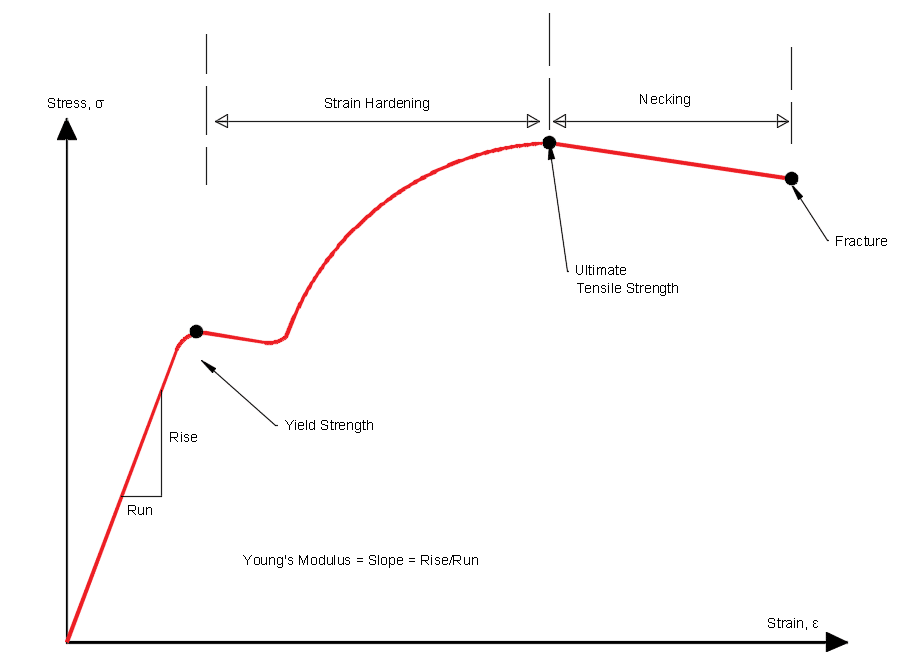

The ultimate tensile strength (denoted \(\sigma_{uts}\)) as can be seen as the highest point in the graph below, and we can see the stress decreases after this point. It is located in the plastic zone of the material.

The SI units for Ultimate tensile strength is MPa (N/mm2).

Typical Ultimate Tensile Strength Table

| Steel, structural ASTM A36 steel | 250 | 400–550 |

| Steel, 1090 mild | 247 | 841 |

| Chromium-vanadium steel AISI 6150 | 620 | 940 |

| Steel, 2800 Maraging steel | 2617 | 2693 |

| Steel, AerMet 340 | 2160 | 2430 |

| Steel, Sandvik Sanicro 36Mo logging cable precision wire | 1758 | 2070 |

| Steel, AISI 4130, water quenched 855 °C (1570 °F), 480 °C (900 °F) temper | 951 | 1110 |

| Steel, API 5L X65 | 448 | 531 |

| Steel, high strength alloy ASTM A514 | 690 | 760 |

| High-density polyethylene (HDPE) | 26–33 | 37 |

| Polypropylene | 12–43 | 19.7–80 |

| Cast iron 4.5% C, ASTM A-48 | 130 | 200 |

| "Liquidmetal" alloy[citation needed] | 1723 | 550–1600 |

| Beryllium99.9% Be | 345 | 448 |

| Aluminium alloy2014-T6 | 414 | 483 |

| Polyester resin (unreinforced) | 55 | 55 |

| Polyester and chopped strand mat laminate 30% E-glass | 100 | 100 |

| S-Glass epoxy composite | 2358 | 2358 |

| Aluminium alloy 6061-T6 | 241 | 300 |

| Cupronickel 10% Ni, 1.6% Fe, 1% Mn, balance Cu | 130 | 350 |

| Brass | 200 + | 500 |

| Tungsten | 941 | 1510 |

| S-Glass | N/A | 4710 |

| Basalt fiber | N/A | 4840 |

| Marble | N/A | 15 |

| Concrete | N/A | 2–5 |

| Carbon fiber | N/A | 1600 for laminates, 4137 for fibers alone |

| Carbon fiber (Toray T1100G) (the strongest human-made fibres) | 7000 fibre alone | |

| Bamboo | 350–500 | |

| Spider silk (see note below) | 1000 | |

| Spider silk, Darwin's bark spider | 1652 | |

| Silkworm silk | 500 | |

| Aramid (Kevlar or Twaron) | 3620 | 3757 |

| UHMWPE | 24 | 52 |

| UHMWPE fibers (Dyneema or Spectra) | 2300–3500 | |

| Vectran | 2850–3340 | |

| Polybenzoxazole (Zylon) | 2700 | 5800 |

| Wood, pine (parallel to grain) | 40 | |

| Bone (limb) | 104–121 | 130 |

| Nylon, molded, type 6/6 | 450 | 750 |

| Rubber | – | 16 |

| Boron | N/A | 3100 |

| Silicon, monocrystalline (m-Si) | N/A | 7000 |

| Ultra-pure silica glass fiber-optic strands | 4100 | |

| Sapphire (Al2O3) | 400 at 25 °C, 275 at 500 °C, 345 at 1000 °C | 1900 |

| Diamond | 1600 | 2800 |

| Carbon nanotube (see note below) | N/A | 11000–63000 |

| Carbon nanotube composites | N/A | 1200 |

| High-strength carbon nanotube film | N/A | 9600 |

| Iron (pure mono-crystal) | 3 |

What is Tensile Strength?

The tensile strength of a material is its ability to resist tensile stress (i.e. force required to pull something, beam, or rope) before it fails/factures.

When steel enters into plastic deformation, it undergoes strain-hardening (also known as work hardening). The strength of the material increases during the phase and the magnitude of tensile strength is at its highest before necking occurs.

What is Necking?

Necking is a phenomenon which occurs only to a few materials, and it is at this point the cross-sectional area reduces and the material weakens. This process occurs until failure.

What is Yield Stress?

Yield Stress or yield strength is the point in the stress strain curve of a material when the strain becomes permanent, and any deformation in the material is permanent.

Note – As a material is loaded, it initially undergoes, elastic deformation and strain, which is reversible once the load is removed. Once it goes past the yield stress/strength, the deformation is permanent, even if the load is removed.

This is important in the design of any structure, infrastructure, or product, as engineers generally design in the elastic region.

We keep the load in the elastic area to keep any engineering products/structures safe from failure (i.e, product is safe from plastic deformation).

In design calculations, we use factors of safety for the applied load and the material. The applied load can be multiplied in the region between 1 and 2. Also, the stress the material (allowable stress) can take is also factored and this can be in a region between 1 and 2.

These factors of safety ensure contingency for any miscalculations or unforeseen additional loads, and also any material defects or imperfections.

Engineers do undertake designs using the ultimate tensile strength for structures or mechanical parts that are subjected to large loads. However, they need to take into account permanent deformation and strain, as the structure/parts, will not be the same due to a change in its crystal structure.

An example is a metal plate with bolt holes. If the plate is subjected to large loads greater that its yield stress, it will undergo permanent strain. Once the load is released the metal plate will not go back into its original shape and the bolt holes will have changed shapes. This may result in the bolts not fitting anymore!!