Typical Values of Young's Modulus of Materials

Table of Contents

What is the Young's Modulus of Steel?

The Young’s modulus of steel (also referred to as modulus of elasticity of steel) is between 190 – 210 GPa at room temperature, which is around 27500 ksi to 31200 ksi. The steel young modulus is a measure of its stiffness/ resistance elastic deformation to tensile loads.

The reason for differing values of young’s modulus of steels is due to the manufacture process, which accounts for the amount of impurities in the steel and the type/grade of steel specified.

The unit of of Young’s Modulus is usually taken as Gigapascal (GPa) which is Pascals x 109

The European standard states the young’s modulus of steel as 210,000 MPa in accordance to EN 1993-1-1 Section 3.2.6.

Carbon Steel Elastic Modulus table

| Material | Young's Modulus in GPa | Young's Modulus in ksi |

| ASTM A228 | 210 | 30458 |

| ASTM A36 | 200 | 29008 |

| AISI 1010 | 205 | 29700 |

| AISI 1018 | 205 | 29700 |

| AISI 1020 | 205 | 29700 |

| AISI 1025 | 190-210 | 27557-30458 |

| AISI 1040 | 190-210 | 27557-30458 |

| AISI 1045 | 205 | 29700 |

Stainless Steel Elastic Modulus table

| Material | Young's Modulus in GPa | Young's Modulus in ksi |

| Grade 316 | 193 | 27992 |

| Grade 405 | 200 | 29008 |

| Grade 440C | 200 | 29008 |

Young's Modulus of Steels and Common Metals

| Material | Young's Modulus (GPa) |

| Aluminum Bronze | 120 |

| Aluminum | 69 |

| Aluminum Alloys | 70 |

| Antimony | 78 |

| Beryllium (Be) | 287 |

| Beryllium Copper | 124 |

| Bismuth | 32 |

| Brass | 102 - 125 |

| Brass, Naval | 100 |

| Bronze | 96 - 120 |

| Cadmium | 32 |

| Carbon Fiber Reinforced Plastic | 150 |

| Carbon nanotube, single-walled | 1000 |

| Chromium | 248 |

| Cobalt | 207 |

| Copper | 117 |

| Diamond (C) | 1220 |

| Gold | 74 |

| Grey Cast Iron | 130 |

| Inconel | 214 |

| Iridium | 517 |

| Iron | 210 |

| Lead | 13.8 |

| Magnesium metal (Mg) | 45 |

| Manganese | 159 |

| Molybdenum (Mo) | 329 |

| Monel Metal | 179 |

| Nickel | 170 |

| Nickel Silver | 128 |

| Nickel Steel | 200 |

| Niobium (Columbium) | 103 |

| Osmium (Os) | 550 |

| Phosphor Bronze | 116 |

| Platinum | 147 |

| Rhodium | 290 |

| Sapphire | 435 |

| Silicon | 130 - 185 |

| Silicon Carbide | 450 |

| Silver | 72 |

| Steel, stainless AISI 302 | 180 |

| Steel, Structural ASTM-A36 | 200 |

| Tantalum | 186 |

| Thorium | 59 |

| Tin | 47 |

| Titanium Alloy | 105 - 120 |

| Tungsten (W) | 400 - 410 |

| Tungsten Carbide (WC) | 450 - 650 |

| Uranium | 170 |

| Vanadium | 131 |

| Wrought Iron | 190 - 210 |

| Zinc | 83 |

How do we find the Modulus of elasticity of steel?

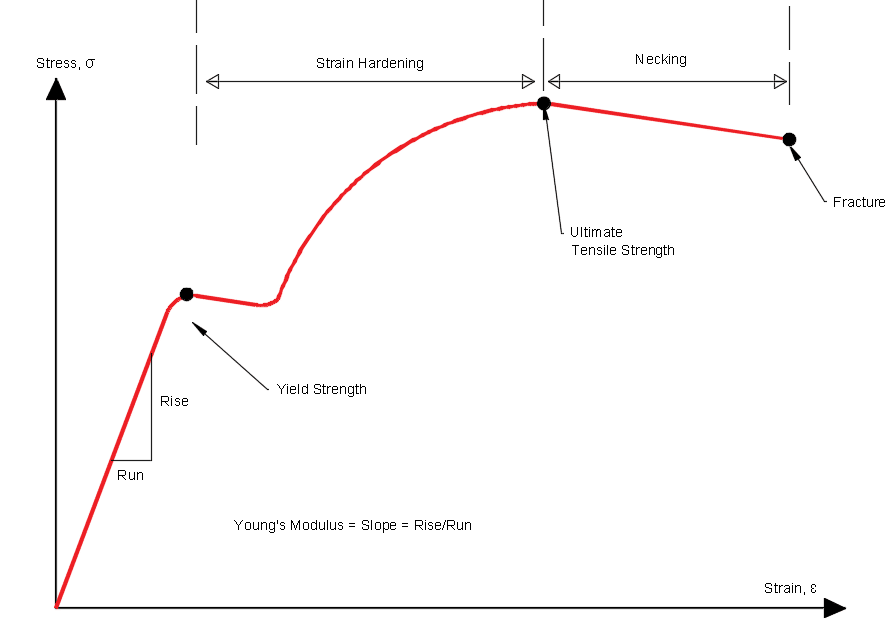

The steel elastic modulus is determined from experimental data of a tensile test on a material specimen. The tensile test applies a tensile stress, and the deformation (strain) is measured at each instance the load increases.

A stress strain curve is plotted graphically, and the steel elastic modulus is the slope of the linear elastic part of the curve. Through Hooke’s law, we can define the Young’s modulus of steel to be \(E = \sigma / \varepsilon\).

The equation above has been rearranged from this formula: \(\sigma = E. \varepsilon\).