Types of Floor Construction

Table of Contents

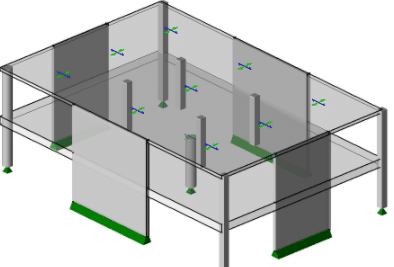

Types of Floor Construction: Composite metal deck slabs

In steel frame structures, it is common to use a composite metal deck floor system. The metal deck is laid out on the secondary and primary steel beam sections and shear studs are arc welded between the metal deck and the top flange of the beam. Concrete is then poured onto the metal deck to the specified depth (varies between 150mm – 250mm thick). This forms a composite section between the steel beam and concrete section, which increases the resistance of the composite beam to bending, shear and deflection.

The composite floor consists of a metal deck, and suppliers are Tata steel, Northern Deck and many other manufactures. They are usually between 0.7mm – 1.2mm gauge thickness, and it is important to note that the higher gauge has quite a difference in costing.

It is important to note that during construction, the concrete is wet/fluid and has an increased pressure load onto the metal deck and the deck will also be subjected to construction loading (i.e, hand vibration tools for concrete and tamping rails) (1.5 kN/m2 is a typical construction load). As the deck deflects and starts sagging, there will be a build-up of concrete pooling at the centre or area with the largest deflection (common to design for an additional 20mm concrete ponding). The deflection of the deck needs to be considered during construction and whether propping of the beams needs to be undertaken.

Precast slabs

Types of floor construction include precast slabs, which are used in construction of new buildings such as schools, shopping centres and residential areas. They are often used in steel frame structures and supported off secondary and primary steel beams and can be designed as composite beams, but this depends on the method of construction and tying details. They are quick and easy to construct on site and can be lifted into position.

Precast slab can have structural or non-structural topping which is typically a screed (reinforced in structural topping) between 75mm – 100mm. This allows diaphragm action in the slab which transfers lateral wind forces back to steel bracing or concrete core (depends on stability system).

In addition, it is important to determine the construction sequence using precast planks and how its sites on the steel beams. Does it bear on the top flange of a Universal Beam section or on the bottom flange of an Asymmetric Beam/Slimflor beam?

If the plank bears on the bottom flange of the beam, then torsional forces need to be considered as the force is eccentric to the web of the beam. Also, the width of the flange needs to be considered on whether there is enough bearing for the plank to sit on (i.e. typically minimum bearing of 80mm on each side).

Overall, precast planks are good when considering the speed of construction and the ability to reduce the structural zones (i.e. the floor depth is reduced) and there will be increased floor-to-ceiling height.

Concrete Flat Slab

The flat slab floor type is an in-situ concrete floor which is commonly used in Reinforced concrete frame buildings. The floor slab will be designed as either as a two-way spanning slab or one-way spanning slab supported on concrete beams.

During construction, formwork to the underside of the floor is required which can either be timber/metal formwork and propped using either acrow props or heavy-duty soldiers (RMD kwickform props or Mabeyhire props). The formwork is then removed once the concrete slab has cured, set and achieved the minimum strength as specified by the designers.

The flat slab approach is a very useful for buildings where floor to ceiling heights are restrictive or where there are large mechanical services and ductwork required as the soffit is clear, and ducts can pass through easily.

There are other types of concrete slabs which include one-way spanning slabs, two-way spanning slabs, waffle and ribbed slabs, which are all useful depending on the building and design scenario.

Waffle slabs are a common feature for older car parks because the deeper sections with reduced concrete volume provided adequate strength for the floor whilst limiting deflection and cracking. However, the complexity of formwork is what stops it being a widely used from among the many types of floor construction.

It is important to note that concrete frames and flat slabs are very good when looking at vibration and frequency in the design of hospitals. MRI and X-ray rooms and other highly intensive equipment that induce large vibrations or radiation can be mitigated using a concrete framing system.

In addition, these types of floor construction for concrete frame buildings and deep floor sections contribute to the overall weight of the building and requires larger foundations (i.e. a lightweight floor system may save money on the number of piles requires in piled foundations).

Timber/CLT Flooring

This floor type is a lightweight solution where the floorboards which would be either CLT or timber panels are supported on timber Joists. This is commonly found in residential masonry properties where the applied loading and span of the room are quite small.

Types of floor construction such as CLT is now being used more often as a sustainable alternative to concrete flooring, but this depends on how the CLT/timber is sourced (i.e. is the CLT manufactured and transported abroad; therefore, using concrete locally might be a sustainable than using CLT).

In addition, the lightweight flooring system means a significant reduction on column and foundation loads. This means column weights can decrease as well as reducing the number of piles in high rise buildings.

This Post Has One Comment

This is really useful stuff. Thanks a lot