Types of Concrete Floor Slabs

Table of Contents

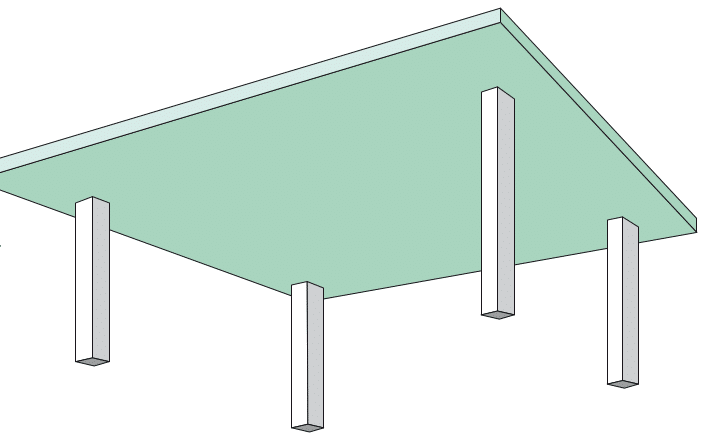

Types of Concrete floor slabs : Flat slab

Flat slabs are generally a reinforced concrete floor slab using mesh reinforcement (i.e. A252, A393 etc.) and is supported on columns or corbelled columns without beams. This is easy to construct using a simple arrangement of formwork and propping.

Formwork is typically either proprietary panels (metal/plastic) which needs to be designed by temporary design engineers. For concrete frame building with multiple floors, back propping using acrow props or heavy-duty soldiers is often required.

Flat slabs are a type of concrete floor slab which provides a clear floor without any obstructions or beams on the underside of the soffit. This is extremely useful in buildings which have a tight service constraint (i.e. Mechanical engineers often require large space for their ventilation systems).

An important design aspect of flat slabs is design for punching shear around columns, which is defined as a concreted load applied to a small area (i.e, column reactions in a slab). This type of failure mechanism is critical in slabs and often designed using punching shear reinforcement (shear rails) to mitigate against high concentrated shear loads.

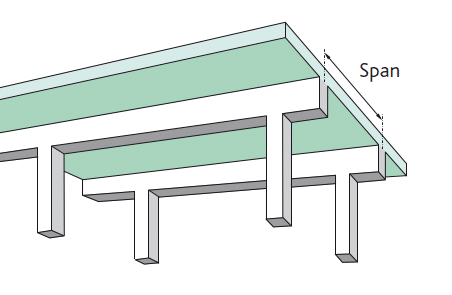

One-way slab

One-way slabs are reinforced flat slabs spanning in one-direction supported on beams which are supported on columns. Construction is like a flat which uses formwork and back-propping of slabs, but more formwork is required to form concrete beams.

A disadvantage is there is a reduced area for services to span due to the additional concrete beam which reduces the flexibility for M&E requirements.

Shear in the beams and punching shear in slab around concreted point loads need to be checked in design as well bending stress and deflection checks.

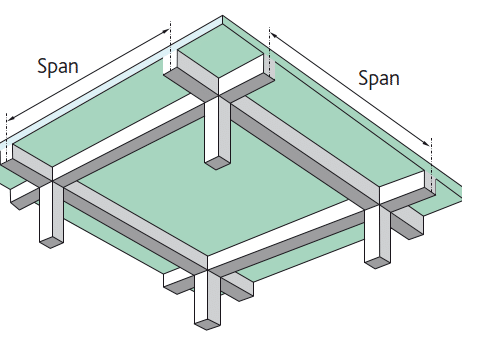

Two-way slab

Types of concrete floor slabs include two-way slabs which, are reinforced slabs which span in both directions supported on beams which are supported on columns. Additional formwork is needed for the additional beams, but deflection of the slab is decreased because of the increased stiffness of the slabs from the beams.

However, there is even less flexibility for M&E services due to the additional beams in both directions and this needs to be resolved early on in a design or conveyed to the Mechanical engineers and architects to allow them to co-ordinate or make some design changes.

Waffle slab

Waffle slabs are types of concrete floor slabs with concrete ribs running in in both directions on the underside of the slab. They are useful as they are lighter and stiffer than a flat slab, which reduces the load-take down on foundations potentially reducing column and foundation sizes.

They are generally constructed on site where concrete is poured onto formwork or precast elements constructed off site and then transported and connected on site.

These types of concrete floor slabs are good for buildings that require less vibrations (hospitals and gyms), bigger spans using less materials, greater load capacity than one-way slabs.

Holes can be constructed through the ribs to allow services to pass but this needs to be always checked with the structural engineer before any changes are made.

However, the waffle slab is thicker/deeper than a traditional flat slab, so this needs to be co-ordinated with architects to check if floor to ceiling heights are adequate but also Mechanical engineers to check if there is enough space for their services and ventilation kits.

Hollow core slabs

More types of concrete floor slabs include Hollow core slabs which is essentially a reinforced flat slab with a series of openings in the slab which depends on the type of manufacturer and design requirement.

These slabs will be typically lighter than a traditional flat slab and are generally supported on concrete or steel beams connected to columns. Depending on the type of construction, the slab can a flat soffit finish which allows a clear area for services as well as the openings which can also be used for services.

Hollow core slabs tend to be constructed off-site and are precast elements which are lifted in planks on site. This is commonly used in steel frame structures and the steel asymmetric sections or slimfloor sections can be used which allows the beam to be part of the floor element. The slab is supported on a flat plate welded to the underside of the Universal column section. However, torsion needs to be designed for in the permanent and temporary cases as the force from the slabs does not go through the shear centre of the universal column section.

Practically, the largest UC beam that can be used for slimfloor beams or asymmetric beams are UC 305×305 as the precast planks’ depths range from 150 – 300mm. This is due to structural topping (75mm – 100mm reinforced screed) which needs to over the top flange of the beam and have enough room for reinforcement bars.

Structural topping is used to connect the pre-cast planks and allows diaphragm action on the floor area, which is important for the stability of the structure. The diaphragm action of the floor plate allows the transfer of lateral forces (horizontal wind loads) back to the bracing system or shear core.