Masonry Properties

Table of Contents

Masonry construction and its uses

Masonry construction is common within the UK and other parts of the world, using bricks made from dried clay are joined together using mortar or other adhesives to build walls, pavements and other elements. Brick sizes vary between countries as well as there types and materials used in manufacture of bricks.

The most common manufactured types of bricks are ‘fired bricks’ where clay bricks are burned to high temperatures in a kiln, which are long-lasting and strong as a building material. Historically, mud bricks/air-dried bricks were used in early history by the Ancient Mesopotamians and other civilizations, but this types of brick has low compressive strength.

There are many types of bricks that are used such as facing bricks, engineering bricks, common bricks, concrete bricks, stone masonry, concrete blocks and calcium silicate bricks. These types of bricks are used for different purposes depending on the suitability for the construction work, but it also depends on what materials are locally available.

Types of Bricks in masonry construction

The most common types of bricks used in construction are the following:

- Solid bricks – They do not have holes exceeding 25% of the brick volume, or ford not exceeding 20%.

- Perforated bricks – they have holes exceeding 25% of the brick volume. The holes are less than 20mm wide or 500mm2 in area.

- Hollow bricks – They have holes in excess of 25% of the volume of brick. (holes larger than perforated bricks)

- Cellular bricks – They have holes closed at one end exceeding 20% of the volume of brick.

- Special shapes – They are non-standard shapes

- Paving bricks – They are used for walkways or roadway.

- Engineering brick – Hard, dense brick with low water porosity.

- Acid bricks – acid resistant bricks.

Facing bricks

Facing bricks are a very common brick type used in the UK housing construction market. They have an impact on the buildings appearance and are specified based on their color and texture, due to the manufacturing. The costs of facing bricks vary depending on the finish and appearance that is desired by the client (determined by the manufacturing process).

Engineering bricks

Engineering bricks have a high compressive strength and low rate of water absorption, as the clay bricks are burned to high temperatures in the kiln during the manufacturing process . They are used in engineering projects where resistance to water penetration or frost damage is required, such as sewers, retaining wall, groundwork and manholes. They are rated as Class A or Class B, where class B bricks are commonly specified.

Common bricks/Burnt clay bricks

Common bricks are not widely used in the UK and are a cheap and low quality brick type, with lower strength and resistance to water and frost damage. However, there are suitable for internal walls where they can be hidden by internal finishes.

Burnt clay bricks are categorized into four classes, which are used for different purposes in construction. The four types are also manufactured differently which affects it properties.

- First class bricks – They are good quality bricks and are molded by table-molding and burnt in large kilns. They are stronger and expensive compared to the other classes.

- Second Class bricks – They are moderate quality bricks and molded using ground-molding process and manufactured by burning in kilns. However, they do not have smooth surfaces, and shapes are irregular and smooth plastering is required on the brick.

- Third Class bricks – These bricks are of poor quality bricks used for temporary structures and are not suitable for rainy areas. The surface of these bricks are rough.

- Fourth Class bricks – These bricks are very quality bricks and not used in structures. They can be crushed and used as aggregates in a concrete mix. These types of bricks are made when the bricks are over-burned and overheated, making it brittle and weak.

Calcium Silicate Bricks

Calcium silicate bricks are made out of clay with the addition of lime binding the silicate material and pigments that can be added during manufacture to change its colours.

They were mainly used for non-load bearing walls, but advancements in manufacturing techniques increased the compressive strength, allowing load-bearing walls. They have different movement characteristics and spacing requirements for joints will be different. They also have good freeze/thaw resistance.

Concrete Bricks

Concrete bricks are made from solid concrete and are similar in size and shape to clay and calcium silicate bricks, and the spacing of the joints are different to the other brick types. They can be produced in different colours depending on the type of pigment added during manufacture.

Common uses for concrete bricks include fences and facades due to its aesthetic appearance. It is also used for internal wall and covered by internal finishes.

Stone Masonry

Stone masonry is a construction material which is not widely used anymore due to high cost of labour, high skill set. However, it may be economical to use in areas where the manufacture and extraction of stone blocks are cheap and readily available.

Famous buildings that were made using stone are the Egyptian Pyramids, Taj Mahal, Parthenon, Great wall of China and other structures.

Concrete Blocks

Concrete blocks are made in various sizes and are a common building material in construction. They are used for the construction of double skin walls, forming the inner leaf in walls. Other common construction works include retaining walls, partitions and foundations.

They can also be hollow core blocks making it lighter and improving the insulation properties. Different types of blocks can be formed depending of the constituents and manufacturing process, such as dense blocks, lightweight blocks and aerated blocks.

Types of Brick Bonds

Masonry walls are constructed in brick bonds, which is an arrangement of bricks. They are laid as soldiers (standing upright), stretchers (laid lengthwise along the wall) or headwise (laid width wise along the wall). The bonding patterns allow the loading to be distributed through the structure, and stabilise the wall.

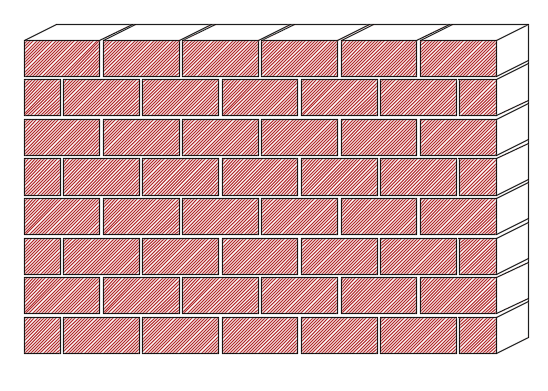

Stretcher Bond

This is a common bond and used for single leaf walls. The is also called a half-brick thick walls.

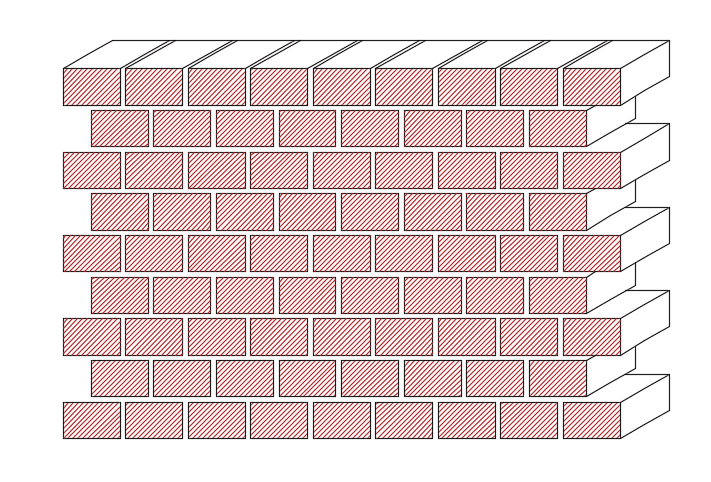

English Bond

This bond results in brick course laid alternatively with headers and stretchers. The width of the wall is one full brick length or referred to as a brick-thick-wall. This results a strong bond which is common used for construction work such as bridges and walls.

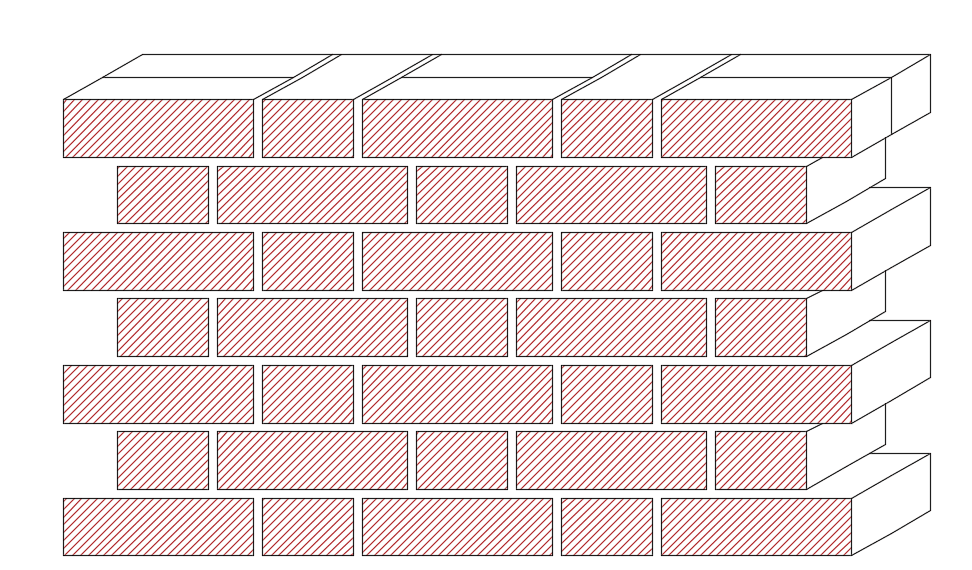

Header Bond

This bond refers to brick coursing that is laid flat with headers offset by half a brick. This has a similar bond to the stretcher bond. The width of the wall is one full brick length or referred to as a brick-thick-wall.

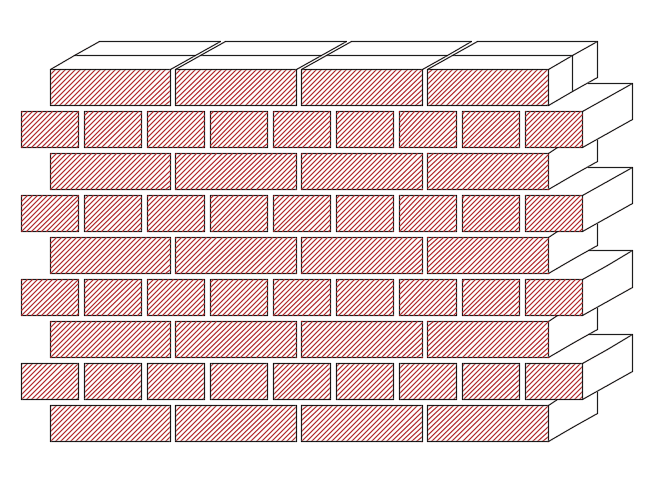

Flemish Bond

This type of bond is made laying down headers and stretchers alternatively in each course. This results in a strong bond, and is one brick thick.