NDT methods for concrete

Table of Contents

Non-Destructive testing (NDT) methods: Pull-out test

The pull-out test measures the force the to extract standard embedded inserts (special steel rods and casts into concrete) from the concrete surface. The magnitude of the force is measures and the recorded value correlates to the compressive strength of the concrete.

There are two types of inserts which are a post fixed test (insert installed after the concrete has set) and cast in tests where the insert is positioned in fresh concrete before pouring.

The tests consist of a 25mm insert (LOK tests developed by Kierkegarrd-Hansen) and the force required to remove the insert is called the “Lok-strength “.

For example, if the concrete was originally C40/50 and it was discovered to have a compressive strength of 20 N/mm2, we can immediately determine the capacity of the concrete and what strengthening works needs to be required or if the concrete has deteriorated beyond the point of repair.

However, the pull-out tests don’t indicate the fundamental failure mechanism, where the 25mm insert is pulled out only, or if the concrete provides any additional resistance. The pull-out tests can’t determine the quality of concrete when looking at aggregate size, cement mortar percentage as these all affect the pull-out tests.

Ultrasonic Pulse Velocity Test (UPV)

UPV is a type of Non-Destructive testing (NDT) methods assessing the concrete composition, density, elastic composition, internal cracks, and depth of cracks.

This test is conducted through using an electro-acoustical transducer on the surface of the concrete, measuring the time taken for an ultrasonic pulse to pass through concrete at the transmitting transducer and receiving transducer.

The transmission time is used to determine the properties of concrete. Higher transmission time indicates a poor quality concrete, cracks or deformities

Lower transmission times indicates good quality concrete (good mix, no cracks, issues in concrete).

Advantages of the tests for determining the following:

- whether concrete is damaged

- honey-combing of concrete

- loss of internal cohesion

Half-cell Potential test

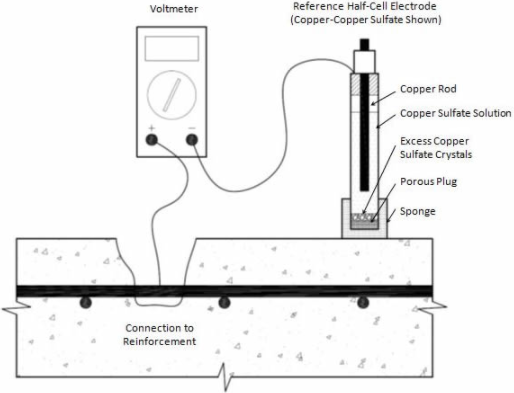

The Half-cell potential tests is used to check if there is any on-going corrosion taking place in reinforced concrete, which is another example of Non-Destructive testing (NDT) methods.

The test is undertaken using a half-cell system and high-impedance voltmeters. An electrical connection is made to the reinforcement and the negative half-cell.

The system detects the flor of ion migration between the concrete and connection points in the concrete. The recorded results are then interpreted to determine where corrosion is taking place. Also, it is recommended that potential surveys are supplemented with tests for carbonation and soluble chloride ion content for more accurate results.

The test only confirms whether corrosion is happening in the reinforcement but not the rate of corrosion or overall condition of the reinforcement. This can only be checked through intrusive testing and exposing the rebar.

Surface Hardness Test

Another Non-Destructive testing (NDT) methods is the standard hammer tests that was developed in 1948 by Swiss engineer Ernst Schmidt. A hammer is used to hit the concrete, and the rebounded hammer records a rebound number, which correlates to a strength property of the concrete. (This is used to establish compressive and flexural properties of concrete).

The test is easy to undertake and inexpensive to determine the concrete properties. However, the results of the testing is affected by the concrete composition, surface smoothness, age of concrete, internal moisture condition, type of coarse aggregate, type of cement. Due to this results being varied, it is better to use another Non-destructive testing method along side this test and compare concrete samples using the standard rebound hammer test.

Pull Off Test

The pull off test is an assessment of the concrete, which involves measuring the tensile force through measuring the force required to pull off a disc that is bonded to the concrete surface with a type of resin (epoxy).