BS EN 1992-1-1 and concrete mixes

Table of Contents

How to specify concrete mix to EC2

Concrete mixes are specified in accordance to Eurocode 2 and the British standard, BS 8500 (Method of specifying and guidance for the specifier) in the UK. This standard is used for concrete mixes for elements/items in the construction industry to ensure the designed concrete structure is adequate against the environment and suitable against applied loadings.

Important factors affecting the concrete mix are the following:

- Exposure classification

- Concrete strength

- Design life of concrete

- Cover to reinforcement

- Cement Type

- Freeze-thaw attack

- Aggressive ground chemicals

Exposure Conditions

Exposure conditions for the concrete mix relates to the environment the concrete is designed and placed. It is important to consider if the concrete is being used as a foundation, a fence exposed to the atmosphere, close to the sea or only used for internal floor slabs, as these all affect the concrete in different ways, with some worse than others.

In accordance to BS8500, exposure classes are categorised by the following:

- XC (Corrosion due to carbonation)

- XD (Corrosion due to chlorides other than seawater)

- XS (Corrosion due to chlorides from seawater)

- XF (Freeze-thaw attack)

- ACEC (Chemical attack by aggressive ground)

Combinations between the XF and ACEC class can occur with the XC, XD, XS classes.

The exposure conditions, class descriptions and examples is shown by table A.1 of BS 8500.

Concrete Strength

Once the exposure class has been determined, the concrete strength needs to be chosen. The designer should already have a minimum strength that their design needs to achieve in order for it to be adequate.

Common design mixes for slabs are C28/35 and C32/40 and C40/50 for columns but this depends on the concrete element and how the elements are designed.

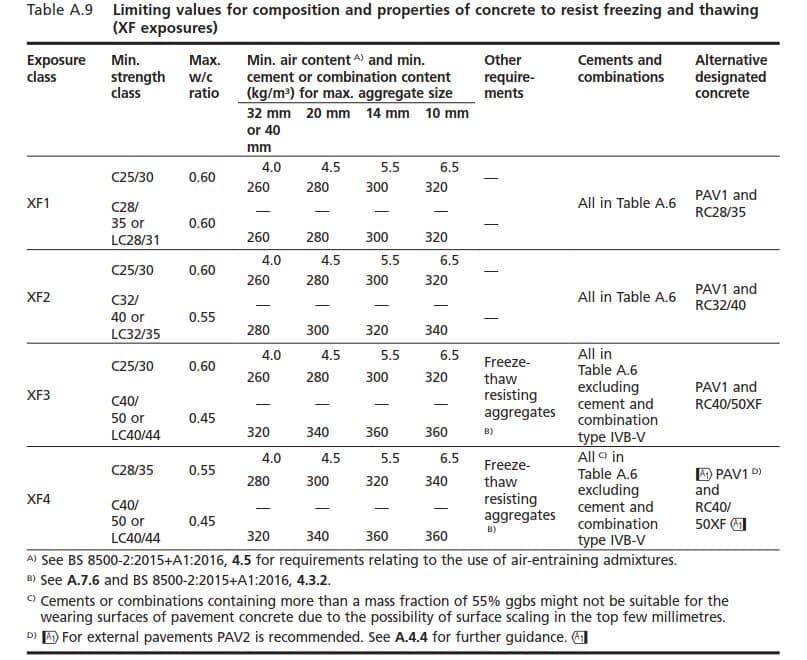

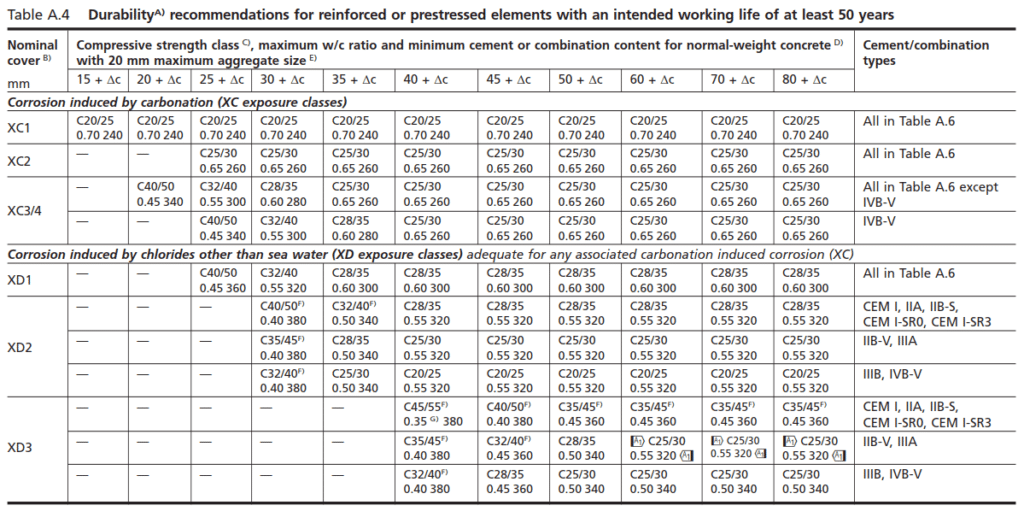

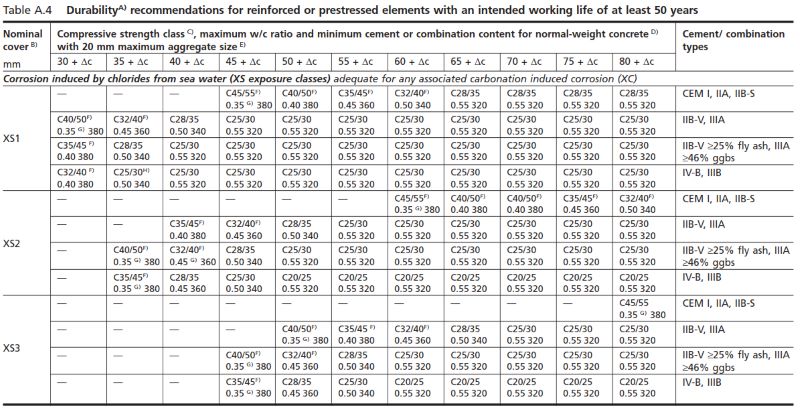

Table A.4 and A.5 go through the compressive strength class of concrete for a 50 year and 100 year design life. These table indicate the allowable cover, maximum water-cement ratio, minimum cement concrete and allowable cement types.

Design life of structure

The design life needs to be classified at the beginning of the project for the structure. The UK national annex to the Eurocodes, NA to BS EN 1990:2002 (Basis of structural design) define the design life of a structure in clause NA.2.1.1.

The British Annex states a 120 year design life for category 5 structures, but table A.5 of BS 8500, which only specifies a design life of 100 years is still adequate to use for category 5 structures/buildings.

Cover to Reinforcement

The minimum cover to reinforcement for durability is defined in Eurocodes and in BS 8500 in table A.4 and 4.5.

When placing reinforcement in concrete mixes, allowable tolerances are required for any deviations, \(\theta\) cdev, which is typically between 5mm and 15mm.

If the reinforced concrete is made in a factory (adequate quality control), \(\theta\)cdev can be taken as 5mm. If it is constructed on site, Eurocode 2 recommends 10mm for \(\theta\)cdev.

The nominal cover is the combined values of \(\theta\)cdev and the minimum cover, cmin (see table A.4 and A.5 of BS 8500)

- cmin = minimum cover

- \(\theta\)cdev = allowance for design deviation

- cnom = cmin + \(\theta\)cdev = nominal cover

Cement Types

The cement types are listed in table A.6 of BS 8500 and the allowable combination types depends on the type of concrete design and cover to reinforcement when looking at table A.4. For example, some cement types might not be suitable for foundations solutions.

The cement types that are used in the United Kingdom is Portland cement, sulfate resisting Portland cement, and Portland cement with varying amounts of fly ash, blast furnace slag and silica fume.

Freeze-Thaw

Freeze thaw attack is caused by water in the concrete freezing, expanding and causing internal pressures, which results in internal cracks. This common where concrete is exposed to rain and freezing, bridge surfaces and other scenarios described in table A.1.

Air entrainment in the concrete mix is required for all freeze-thaw classes. The minimum air content by volume is 4.0%, 4.5%, 5.5%, or 6% with aggregate sizes of 40mm, 20mm, 14mm, and 10mm respectively. Exposure classes XF3 and XF4 require freeze-thaw resisting aggregates.

Producing concrete with higher strengths becomes difficult as approximately, every 1% of additional air entrained, concrete strength will fall by around 5%.

Aggressive Ground Chemicals

When concrete is placed on the ground for foundations (deep/shallow foundations), ground chemicals can affect the durability. This is assessed using BRE Special Digest 1 and is given a ACEC class, a design chemical class (DC class). The DC class is usually determined in the interpretive report for the ground investigation by the geotechnical engineers.

Useful Tables

Table extract from BS 8500 – A.1 : Exposure Classes

| Class Designation | Class Description | Examples |

|---|---|---|

| No risk or corrosion or attack (X0 Class) |

||

| X0 | Very Dry | Unreinforced concrete completely buried in soil classed as AC‑1. Unreinforced concrete permanently submerged in non‑aggressive water. Unreinforced concrete surfaces in cyclic wet and dry conditions not subject to abrasion, freezing or chemical attack. Reinforced concrete surfaces exposed to very dry. |

| Corrosion induced by carbonation (XC Classes) (where concrete containing reinforcement or other embedded metal is exposed to air and moisture) |

||

| XC1 | Dry or permanently wet | Reinforced and prestressed concrete surfaces inside enclosed structures except voided superstructures and areas of structures with high humidity. Reinforced and prestressed concrete surface permanently submerged in non‑aggressive water |

| XC2 | Wet, rarely dry | Reinforced and prestressed concrete surfaces permanently in contact with soil not containing chlorides. |

| XC3 and XC4 | Moderate humidity or cyclic wet and dry | External reinforced and prestressed concrete surfaces sheltered from, or exposed to, direct rain. Reinforced and prestressed concrete surfaces subject to high humidity (e.g. poorly ventilated bathrooms,kitchens) Reinforced and prestressed concrete surfaces exposed to alternate wetting and drying Interior concrete surfaces of pedestrian subways not subject to de‑icing salts, voided superstructures or cellular abutments |

| Corrosion induced by chlorides other than from sea water (XD Classes) (where concrete containing reinforcement or other embedded metal is subject to contact with water including chlorides including de-icing salts, from sources other than from seawater) |

||

| XD1 | Moderate humidity | Reinforced and prestressed concrete wall and structure supports more than 10 m horizontally from a carriageway Parts of structures exposed to occasional or slight chloride conditions Bridge deck soffits more than 5 m vertically above the carriageway |

| XD2 | Wet, rarely dry | Reinforced and prestressed concrete surfaces totally immersed in water containing chlorides Buried highway structures more than 1 m below adjacent carriageway |

| XD3 | Cyclic wet and dry | Reinforced and prestressed concrete walls and structure supports within 10 m of a carriageway Bridge parapet edge beams Buried highway structures less than 1 m below carriageway level Reinforced pavements and car park slabs |

| Corrosion induced by chlorides from sea water (XS Classes) (where concrete containing reinforcement or other embedded metal is subject to contact with seawater or airborne salt origination from sea water) |

||

| XS1 | Exposed to airborne salt but not in direct contact with sea water | External reinforced and prestressed concrete surfaces in coastal areas |

| XS2 | Permanently submerged | Reinforced and prestressed concrete surfaces and completely submerged or remaining saturated, e.g. concrete below mid-tide level |

| XS3 | Tidal, splash and spray zones | Reinforced and prestressed concrete surfaces in the upper tidal zones and the splash and spray zones, including exposed soffits above sea water |

| Freeze‑thaw attack (XF classes) (where concrete is exposed to significant attack from freeze‑thaw cycles whilst wet) |

||

| XF1 | Moderate water saturation without de‑icing agent | Verticl concrete surfaces such as facades and columns exposed to rain and freezing Non‑vertical concrete surfaces not highly saturated, but exposed to freezing and to rain or water |

| XF2 | Moderate water saturation with de‑icing agent | Concrete surfaces such as parts of bridges, which would otherwise be classified as XF1, but which are exposed to de‑icing salts either directly or as spray or run‑off |

| XF3 | High water saturation without de‑icing agent | Horizontal or near horizontal concrete surfaces, which are exposed to freezing whilst wet Concrete surfaces subjected to frequent splashing with water and exposed to freezing |

| XF4 | High water saturation with de‑icing agent or sea water | Horizontal concrete surfaces, such as roads and pavements, exposed to freezing and to de-icing salts either directly or run off Concrete surfaces subjected to frequent splashing with water containing de-icing agnets and exposed to freezing |

Table extract from BS 8500 – A.6 : Cement and Combination types