Understanding Slump Classes

Table of Contents

What is "Concrete Slump Class"?

The concrete slump class refers to the workability and consistency of a fresh concrete mix. This is measured by subjecting a fresh concrete batch with a slump test. The higher the slump of the concrete, the more fluid it is, and a lower slump results in a drier concrete mix. Concrete and mortar mixes that have a higher water content will have higher slump and lower water content results in a lower slump. There is a direct correlation between slump and the water content in concrete mixes.

What is "Concrete Workability"?

Concrete workability is a broad term but refers to how easily fresh concrete can be mixed, placed, consolidated and finished with minimal loss of homogeneity. The workability of concrete has a direct relationship with the strength, quality and appearance on the concrete and its required application. The following factors affects concrete workability:

Water/cement ratio – A higher ratio of cement results in a stronger/compressive strength concrete, but an incorrect ratio of water to cement will result in poor strength development. However, too much water will make a very workable concrete, but this can cause segregation between the aggregates and cement.

Aggregate size and shape – Smaller/finer aggregates have a higher surface area, which requires more cement paste to over the surfaces, which is less workable when compared with larger aggregates. Crushed aggregates are good as they provide a better bond between the cement and results in a workable concrete.

Admixtures – There are many types of admixtures, which can affect concrete workability and properties. Superplasticizers which are also referred to as high range water reduces, are used in high strength concrete. They improve the flow characteristics of the concrete mix and reduces the amount of water required in the mix without negatively affecting the workability of concrete.

The concrete workability directly correlates to the concrete slump class, and an incorrect ratio of concrete constituents in the mix can badly affect the finished concrete during construction, which may not be realized until after the concrete has set. This is why continuous testing of concrete is essential before, during and after construction. The slump test is an adequate indicator the concrete slump class.

How to carry out a concrete slump test?

The concrete slump test is a simple and easy test that measures the consistency of concrete before it sets. It is useful to check concrete mix batches on site before pouring concrete. In the United Kingdom, the slump test is measured in accordance with BS EN 12350-2. The flow is measured in accordance with BS EN 12350-5. The slump-flow is measured in accordance with BS EN 12350-8.

The test is undertaken using a steel slump cone or Abrams cone, which is placed on a level surface and filled with the concrete mix in 3 equal layers. The cone has an internal diameter of 100mm at the top and 200mm at the bottom with a height of 305mm.

Each time a layer of concrete is poured into the cone, the layer is tamped 25 times to ensure compaction used a metal rod. Once the third layer has been filled to the top of the cone and compacted, the cone is lifted up carefully, and the concrete ‘slumps’ or settles.

The slump of the concrete is measured by taking the difference between the top of the slumped concrete and top of the metal cone.

Concrete slump test results

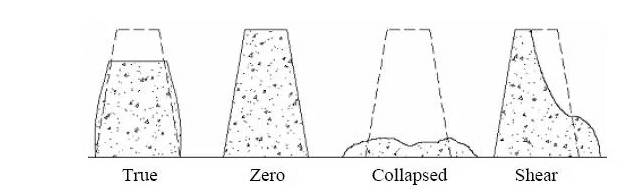

The shape of the concrete mix takes the following forms, true slump, zero slump, collapsed slump and shear slump. The test results determine the concrete slump class.

True slump – This is the only test which is useful in measuring the consistency and workability of the concrete. The concrete slumps, whilst maintaining its overall shape.

Zero slump – This result indicates the mix is to dry with a very low water-cement ratio with low workability, but dry mixes are used in road construction.

Collapsed slump – The concrete mix completely collapses and this result indicates a very high water-cement ratio (too wet or high workability mix) and the slump test is not appropriate.

Shear slump – The mix shears and slips sideways and the slump test needs to be carried out again.

Concrete slump class specification to BS 8500

The concrete slump test results are interpreted using Table B.1 of BS 8500 as shown below. There are 5 consistency classes, ranging from S1 to S5.

Concrete consistency class S4 and S5 have high slump values (high water cement ratio), which can lead to segregation of the aggregates and cement. This can be remedied by using cement additives to ensure the concrete remains workable.

| Specified slump class | Requirement | |

|---|---|---|

| Not less than | Not more than | |

| S1 | 0 | 50 |

| S2 | 40 | 100 |

| S3 | 90 | 160 |

| S4 | 150 | 220 |

| S5 | 210 | - |

What structures can the concrete consistency class be used for?

BS 8500, table A.18 defines the consistence suitability for the type of concrete structure, which is defined below. The concrete slump classes in the table below range from S1 to S4.

| Use of concrete | Form of compaction | Consistence class | |

|---|---|---|---|

| Normal weight concrete | Lightweight concrete | ||

| Cement-bound for reinstatement or base | Tamping, vibrotamper, vibrating plate or roller, roller-compaction | - | - |

| Kerb bedding and backing | Tamping | S1 | |

| Floors and hand placed pavements | Poker or beam vibration | S3 | S2 |

| Large or industrial floors | S3 | S3 | |

| Strip footings | Poker or beam vibration and/or tamping | S4 | - |

| Mass concrete foundations | S3 | - | |

| Blinding | S3 | - | |

| Normal reinforced concrete in slabs, beams, wall and columns | S3 | S3 | |

| Sliding formwork construction | S2 | S2 | |

| Pumped Concrete | S3 | F5 | |

| Vacuum processed concrete | S3 | S3 | |

| Trench fill | Self-weight compaction | S4 | - |

| In-situ piling | S4 | - | |