Types of Concrete

Table of Contents

Introduction

Construction is a rapidly evolving industry with new complex and challenging structures are being built. More often than not, material strength and understanding their characteristic properties make a difference and could be the reason why an innovative project pushes forward or collapses.

This change in construction industry has lead to innovation in the concrete industry where different types of concrete is needed depending on the project criteria.

Concrete compressive strengths now range from 20N/mm2 to 200 N/mm2 (ultra high performance). This is achieved by experimenting with the water/cement ratios, chemical admixtures and aggregates when making concrete.

These special types of concrete are listed below:

- Lightweight aggregate concrete (LWA)

- Autoclaved aerated concrete (AAC)

- Foamed concrete

- High-density concrete

- High-strength concrete (HSC)

- Fibre-reinforced concrete (FRC)

- Sprayed Concrete

Types of Concrete

Lightweight aggragte concrete

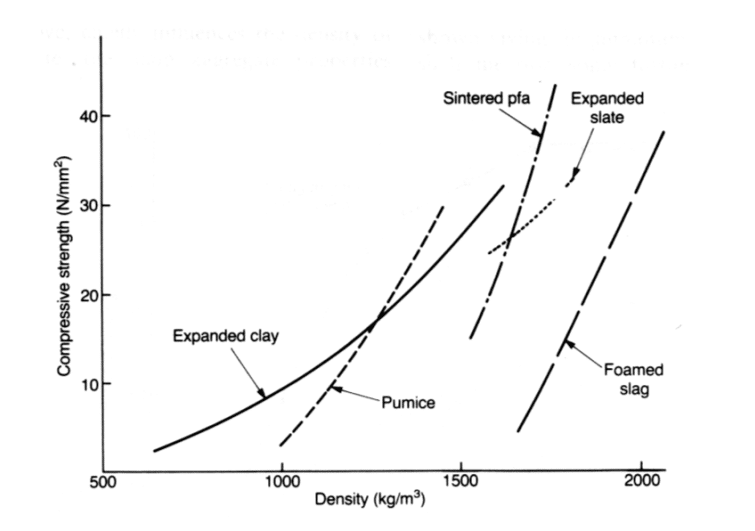

Lightweight aggregate concrete is defined as having an oven dry density of less than 2000 kg/m³ and made with aggregates with a density of less than 2000 kg/m³ .

Only aggregates produced from shale, clay, slate, blastfurnace slag and fly ash possess sufficient strength for structural concrete. Other used in non load bearing applications (e.g. Facades).

Types of lightweight aggregate:

- Pumice; unprocessed naturally occurring volcanic rock.

- Expanded clay or shale (Pellite); Produced by heating suitable to form rounded particles with an open textured interior and a glassy outer skin.

- Sintered P.F.A; made from the ash resulting from the combustion of pulverized coal in power stations.

Structural lightweight concrete is usually ‘semi-lightweight’ in that the course aggregate is lightweight and all or part of the fine aggregate is normal weight (sand has a density between 1600 kg/m³ (dry) and 2000 kg/m³ (wet).

This semi-lightweight concrete will have a density between 1700 and 2000 kg/m³ but still have strength of up to 40 N/mm² at 28 days. Concrete strength will depend on the strength of the lightweight aggregate and mix proportions. Absorption rates are higher than normal aggregates (5 – 20%).

The properties that are a function of tensile strength (shear, development length and modulus of elasticity) are different from those of normal-weight concrete:

- The splitting tensile strength is comparable with normal concrete if continuously moist cured. If air cured can be 25% less.

- The same holds for flexural strength but may be as low as 40%.

- Modulus of elasticity is from 50 – 80% of that of normal concrete.

- This can complicate things in structural design

Benefits of lightweight aggregate concrete:

- Lower foundation costs (due to reduced dead load).

- Reduction in element sizes (cross-sections).

- Lower reinforcement costs.

- If the ground strata has low bearing capacity the reduction in dead loads may allow a greater height of construction on the site.

Autoclaved Aerated Concrete (AAC)

This was developed in the 1920’s by Dr Axel Eriksson and was originally called ‘Gas Concrete’ later called AAC or autoclaved cellular concrete and more recently, porous types of concrete.

AAC is formed by a chemical reaction between finely divided calcareous (usually lime and/or cement) and siliceous materials (usually consists of natural ground sand and/or by-products such as PFA).

The cellular structure is achieved through the following:

- Chemical reaction (to achieve cellular structure). 5-8% of aluminum powder will react with the calcium hydroxide

and water to produce hydrogen bubbles thus doubling the volume of the concrete. - Adding a preformed foam

- Or by introducing air voids by mechanical means into a slurry that contains no course material

- The slurry is usually placed in steel moulds and after rising and setting it is cut into the desired product whilst still soft.

- Then high pressure steam curing is applied.

The characteristic properties of AAC differ from those of other cementitious materials. Due to its porosity, AAC does not provide the same corrosion protection to the steel by more denser concrete. So any reinforcement used should be protected by a suitable surface treatment (galvanising)

AAC is classified as:

Autoclaved aerated concrete (AAC) is about one 4th of the weight of conventional concrete and it typically used for masonry blockwork, lightweight wall and roof panels. It is used in the following applications:

- Beam and block floors

- Pre-cast cellular floors

Foamed Concrete

Foamed concrete is highly workable, low density material which can incorporate up to 50% entrained air. Its generally self-leveling, self compacting and in some cases can be pumped with care. Its made by adding a special foam to the cement mortar slurry. It is ideal for filling redundant voids such as disused fuel tanks, sewer systems, pipes and culverts and it is particularly ideal where access is difficult.

These types of concrete are used in road service trench reinstatement in comparison to granular material which settles and creates un-even load distribution.

Benefits are listed below:

- Very fluid and will fill any voids or cavities with ease without compaction.

- Good thermal insulation properties….so suitable for screeds and filling under floor voids.

- Good for use in roofing construction due to good thermal properties, and sufficiently strong for access (foot and in some cases vehicular).

High Density Concrete

High density concrete or heavyweight concrete are types of concrete has an oven-dry density greater than 2800kg/m³ and its made with aggregate having a particle density greater than 3000kg/m³.

It can be used as counterweights for lifting operations (cranes for example) and underwater pipeline coverings. It is usually and mostly specified for radiation shielding (higher density leads to reduced adsorption of gamma rays!!). Mix design procedures are generally the same as normal but transportation can be an issue (excess consolidation and packing).

Magna dense aggregate used can reach a concrete density of up to 4000 kg/m3

High Strength Concrete (HSC)

The development of high strength concrete has been gradual over many years and its development has continued and is ongoing. In the 1950’s C40 concrete was considered high strength and in the early 1970’s C60 was being produced. These types of concrete are useful for taller buildings or larger span/open areas in buildings.

There was a pressure to innovate due to the following:

- To build high rise buildings (super-high in some cases) with sensible column sizes and increased floor space.

- To achieve huge spans in large bridges.

- To satisfy durability, robustness and resilience requirements.

Cost effective production can be achieved through the following:

- Using readily available concrete making materials of the highest quality in optimum proportioning.

- Carefully selecting, controlling, and combining cement, chemical and mineral admixtures, aggregates and water.

- Conventional construction techniques are used but with high quality control.

- Regular and controlled testing required throughout the entire process.

High strength concrete is achieved through altering its constituents when producing concrete.

Aggregates should be strong and durable. Generally smaller maximum size course aggregate is used. The sand may have to be courser because of the high fines content of supplementary cementitious materials.

High strength concrete mixtures will have a high cementitious materials content and this may include one or

more supplementary cementitious materials. Also, high strength concrete mixtures generally need to have a low water cementitious materials ratio e.g.0.23 to 0.35.

Examples of high strength concrete in use is high rise buildings:

- The economic advantages of high strength concrete for high-rise buildings is mostly realised when the concrete

is used in the columns of high-rise buildings as has been the case in North America and now the Middle East for many years. - The ability to reduce the amount of costly reinforcing steel without sacrificing strength.

- The number of storeys can be increased while maintaining acceptable column sizes at lower levels.

- The reduction in geometrical dimensions of structural elements resulting in reduced dead load (self-weight under gravity).

- The additional local and global stiffness’s provided by high strength concrete with its high modulus of

elasticity reducing sway in upper storeys. - Relatively high early concrete strengths allowing early stripping of formwork and accelerating construction.

Fibre Reinforced Concrete (FRC)

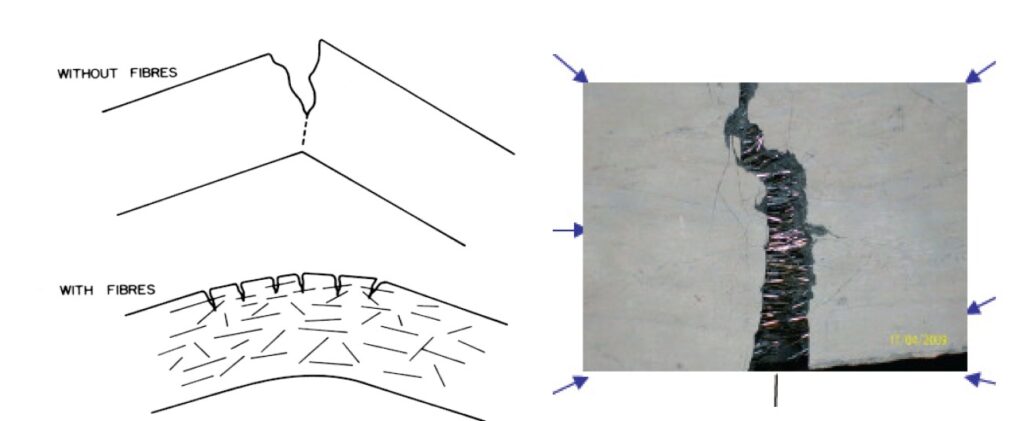

Further types of concrete is the idea of reinforcing relatively brittle building materials with fibres has been known and practised since ancient times. Mud huts constructed from baked clay reinforced with animal hair is a good example. Fibres are extremely effective in inhibiting the rapid development of cracks in plain mortar or concrete.

Their presence in concrete causes crack propagation to develop slowly and progressively with load and enable stress transfer across a cracked section (retention of post-crack strength).

FRC has many benefits when subjected to different types of loads.

- Under conditions of impact loading, the fracture or impact resistance is similarly improved.

- Under conditions of rapid repeated cyclic loading, the progressive propagation of cracks is again effectively inhibited by the fibres, resulting is an improved improvement in fatigue behavior results.

- Under conditions of explosive loading, fibres are particularly beneficial in reducing the amount of fragmentation and the fragment velocities.

There are 4 main types of fibres that are used in FRC:

- Asbestos fibres

- Glass fibres

- Polymeric fibres

- Steel fibres

Glass Fibres:

- Alkali resistant glass (but not immune to alkali attack).

- Reasonably stable over time in concrete.

- Glass is inherently brittle and very prone to damage or abrasion (care needed in transportation and placing the fibres within the concrete), resulting in loss of strength.

- Therefore glass fibres have been restricted to their use in a cement paste matrix where manufacturing process is

controlled. - Strength range achieved can 15 – 20N/mm² in tension and 30-50N/mm² in flexure at a fibre concentration of 6% by volume.

Polymetric Fibres:

- Normally divided into two groups:

- Micro-fibres e.g. Polypropylene

- Macro-fibres

- Mainly influence the early age properties of concrete e.g. Shrinkage and can also improve fire resistance.

- Provide post cracking capacity.

- They have similar dimensions to steel fibres.

- Dosage can be as high as 12kg/m³ for macro-fibres and 0.9kg/m³ for polypropylene.

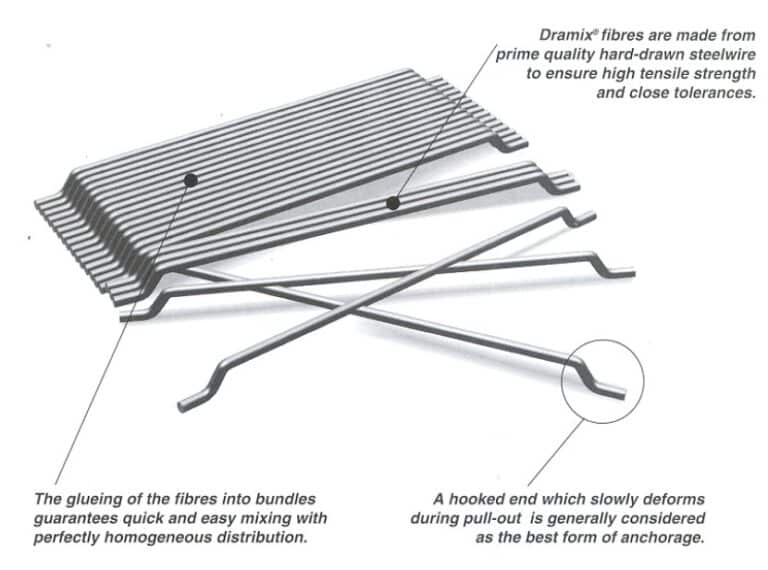

Steel Fibres:

- Steel fibres are classified into five groups according to the method of manufacture:

- Cold-drawn wires

- Cut sheet

- Melt extract

- Shaved cold drawn wire

- Milled from blocks

- Primary aim is to achieve maximum pull-out resistance through their shape.

- Fibres are often used to replace the nominal conventional steel fabric in ground bearing slabs.

Sprayed Concrete

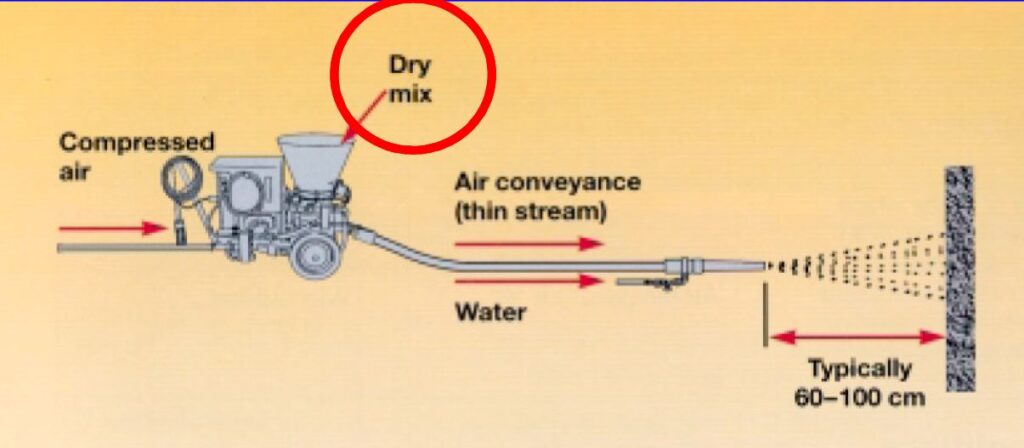

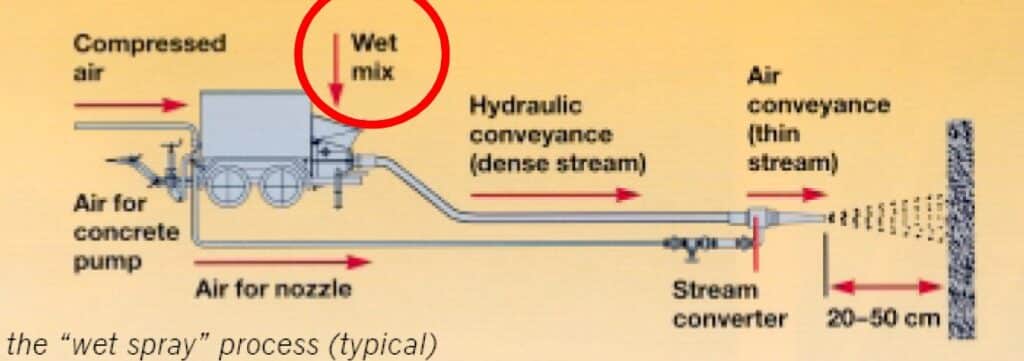

Other types of concrete include sprayed concrete, which is a mortar or concrete pneumatically projected at high velocity from a nozzle to produce a dense homogenous mass.

Sprayed concrete is mortar or concrete pneumatically projected at high velocity from a nozzle to produce a dense homogenous mass.

The benefits of sprayed concrete are the following:

- The force of the jet by which the concrete is projected compacts it despite its zero slump.

- Stays on the surface without sagging (overhead, slopes, radial surfaces etc).

- Normally incorporates admixtures and possibly polypropylene fibres.

- Offers advantages over conventional concrete, in a variety of new construction and repair work.

- Complex shapes cast without complex formwork

Common applications of sprayed concrete are:

- Structural repairs.

- Fire protection for steelwork.

- Tunnel linings.

- Swimming pools.

- River walls.

- Domes.

- Shell structures.