Types of Nanomaterials

Table of Contents

Nanomaterials in concrete

Nanomaterials can be defined as: “Material with any external dimension in the nanoscale or having internal structure in the nanoscale” or defined as materials of less than 500 nanometers as the cementing agent. (Bhatia & Mishra, 2014).

The use of nanomaterials in a concrete mix is an innovative technique, which impacts the mechanical properties in concrete. The strength and durability of concrete is affected, which depends on the type of nanomaterials that is used the mix, as the mechanical property of concrete is affected by its concrete mix ratio.

Nanomaterials are made from two methods called the “top-down approach” and “bottom-up approach”. The “bottom-up approach” (molecular manufacturing) is manufacturing nanomaterials from atoms or molecular components. “The top-down approach” is reducing the size of a large structure to nanoscales, whilst maintaining its original properties. Common nanomaterials used are nanosicila and nano titanium dioxide in concrete.

Is concrete sustainable and are nanomaterials used in construction industry?

Concrete is on the most commonly used material in the construction industry across the world and is made from a mix including cement, water, sand (fine aggregate), small stone or gravel (coarse aggregate). The cement required to produce concrete is one of the most energy intensive industries, which is a major contributor to global warming. Approximately 2600 tonnes of cement is produced yearly (Said, et al., 2012).

The cement making industry is estimated to contribute 5%-7% of man-made carbon emissions into the atmosphere, during the production of cement. This is a problem, which needs to be tackled and cement needs to be reduced or an alternative is needed.

Nanomaterials in concrete is not a common material used in mixes due to many issues, such as unknown consequences in the future. However, the use of chemical admixtures to increase concrete mechanical properties is a common practice in the construction industry.

What is the effect of nano titanium dioxide in concrete?

The addition of nano titanium dioxide in the concrete mix affects the mechanical properties as shown below:

- decrease of workability in concrete

- increase in compressive strength

- increase in corrosion resistant of rebar in concrete

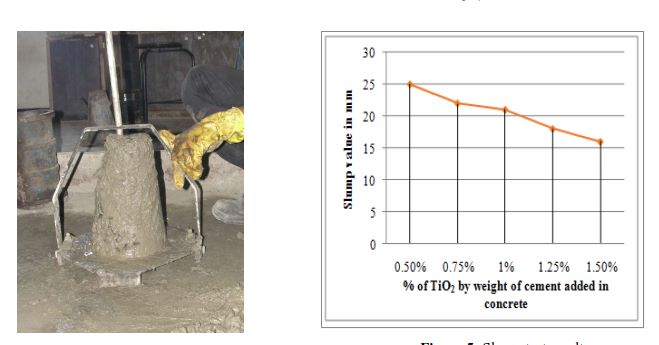

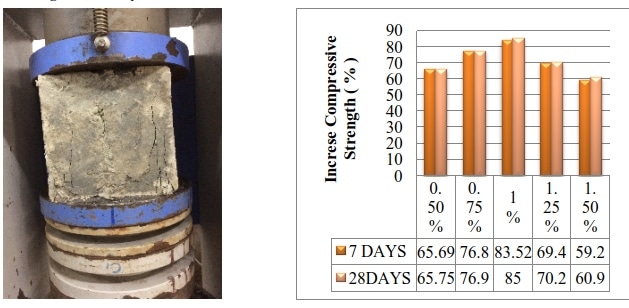

An experiment was undertaken by Jay Sorathiya, Dr Siddhath Shah and Mr Smit Kacha, where they tested the compressive strength and durability of concrete using 0.5%, 0.75%, 1.0%, 1.25%, 1.5% in relation with the weight of cement on grade M20 concrete.

The workability of the concrete sample was tested using the slump test and the compressive strength was tested using a 150mm x 150mm x 150mm concrete. The 7 and 28 days curing cubes are tested under a compression testing machine of 2000 kN capacity.

The experimental results show the slump value decreasing from 25mm to 16mm as the weight of TiO2 increases from 0.50% to 1.5% of TiO2 by weight of cement added in concrete. Slump test values of 0-25mm indicates a very dry mix. The mix is already dry and is becoming less workable when additional TiO2 is used.

The compressive testing indicates that the compressive strength increases dramatically in comparison to M20 concrete. The compressive strength increases a maximum of 85% when 1% TiO2 is used but decreases when additional TiO2 is included. (Sorathiya, et al., 2017).

Another experiment was carried out by Ehsan Mohseni, Waichang Tang and Shanyong Wang in Australia on the the effect of nano titanium on corrosion and thermal performance of structural concrete with Macro-encapsulated PCM.

They also found similar results where the addition of nano TiO2 increased the compressive strength of concrete. The increase was 25% in comparison to a control test, which is much less than the 85% in the previous tests. They believed the increase in compressive strength was due to the nanoparticles filling in the pores making the concrete sample compact. (Moheseni, et al., 2019),

The corrosion of the steel reinforcement was measured using a half-cell potential test. The experiment involved using concrete samples (290mm length x 12mm diameter bar) in a corrosion tank filled with a solution containing 3.5% salt. After 90 days, the samples were then tested to determine the loss of rebar in the sample due to corrosion. It was found that the addition of nano titanium dioxide had a significant impact on the corrosion resistance, where the loss of rebar of rebar was reduced by 56% when comparing it to the control example. (Moheseni, et al., 2019),

What is the effect of nanosilica dioxide in concrete?

The effect of nanosilica dioxide on concrete are:

- increase in compressive strength

- increase in flexural and tensile strength

- decrease in concrete workability (superlasticisers are required)

- early age increase of strength

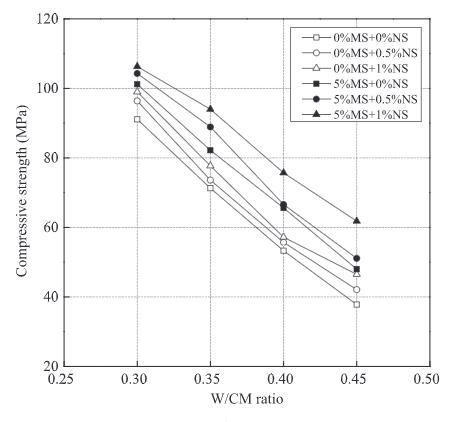

L.G.Li, J.Y.Zheng, J.Zhu and A.K.H. Kwan carried out an experiment where on the combined usage of micro-silica and nanosilica in concrete.

They measured the workability, compressive strength, axial stress-strain curve, elastic modulus, poisson’s ratio and the superplastisers demand of concrete.

It was found that the addition of microsilica and nanosilica decreased the workability and a substantial amount of superplasticisers were required to achieve a workable concrete mix. Also, nanosilica in concrete resulted in more superplasticiser required when comparing it to microsilica in concrete alone.

The compressive strength was tested using cylindrical concrete samples (150mm diameter and 300mm height) and it found that the compressive strength increased with the addition of microsilica and nanosilica and is shown in the results below:

The increase in compressive strength is 16.7% for a combination of 5%MS and 1%NS at a water cement ratio of 0.3 and an increase of 63.5% in compressive strength at a water cement ratio of 0.45. However, it is was noted that there is also a decrease in workability of the concrete but that could be mitigated by increase the amount of superplasticizer, in substantial quantities. (Li, et al., 2018)

Another study was undertaken by S.Chithra, S.R.R. Senthil Kumar and K.Chinnaraju, on the effect of colloidal nano-silica on workability, mechanical and durability properties of High Performance concrete with copper slag as partial fine aggregate.

The experiment consisted of testing high performance concrete with copper slag at a 40% replacement of fine aggregate and replacing Portland cement with nanosilica between a range of 0.5%-3% . They tested the workability, compressive strength, splitting tensile strength and flexural strength.(S. Chithra, et al., 2016).

Their findings were similar to the previous study, where the compressive strength increased but peaked in the sample containing 2% nanosilica. The setting time of the concrete was reduced due to acceleration of hydration noted at 3% nanosilica. (S. Chithra, et al., 2016).

The slump test also indicated that workability decreased as the nanosilica content increased, which required higher dosages of superplasticisers. This is an issue as superplasticisers are expensive and large amounts are required.

What is the effect of carbon nanotubes in concrete?

Ahmed Hassan, Hala Elkady and Ibrahim G.Shaaban undertook a study on the effect of adding carbon nanotubes in reinforced concrete. They measured the compressive and tensile tests, effect on corrosion rate, effect on pull out test and corrosion.

The results of the tests indicate:

- The addition of CNT’s (carbon nano tubes) increased the compressive strength between 7-20% and 10-20% for the tensile strength.

- The CNT improves bond ability of the concrete and this is shown through an electron microscopy analysis where the carbon nanotubes act as bridge across micro cracks

- Concrete with carbon nanotubes have better bond strength of steel reinforcement bars of 12mm and 16mm diameters by 36% and 21% respectively.

- The benefits of carbon nanotubes on the compressive, tensile and bond strength can also be achieved through chemical admixtures.

Future of nanomaterials and important considerations

Nanomaterials in concrete is not a common application which is used in the construction industry due to a need for more research in this topic. However, the benefits include increase in compressive, flexural and tensile strength but at the expense of the workability of the concrete mixture.

Large amounts of superplasticisers are needed to get a workable concrete mix that is suitable on the construction site (depends on the design/construction sequence), but this may roove to be uneconomical in comparison to using chemical admixtures or using higher strength concrete.

However, new buildings and concepts are pushing engineers to the limits of their design and material properties and strength govern the overall design (i.e. can smaller columns, beams, thinner slabs be achieved).

It is important to understand that the long-term effects of nanomaterials in concrete are not understood in terms of their mechanical properties or how they are affected under cyclic loading. Also, the effect of nanoparticles entering the atmosphere and affecting site operatives or the general public is not fully understood. This could be a major health problem and should be investigated before using it in the construction industry.

Further research should be should be undertaken on structural elements such as beams, slabs, columns under cyclic loading over many years, as well as a full size model of a small building. This will show if there structural elements will exhibit the same failure mechanism that are expected in normal beams, columns and slabs.

Nanomaterials in concrete mixes may not be a sustainable option when considering the price, due to required admixtures, but also, as it only replaces a small amount of cement in the mix. However, it is an innovative solution that should be explored and fully understood before it is dismissed but the health and safety aspect should be thoroughly scrutinised.

Biliography

Bhatia, H. & Mishra, K., 2014. Nanomaterials in Concrete: A Review of Their Synthesis, Properties, Applications and Future Developments. Ahmedabad, s.n., pp. 472-474.

Li, L.G., Zheng, J.Y., Zhu, J. and Kwan, A.K.H., 2018. Combined usage of micro-silica and nano-silica in concrete: SP demand, cementing efficiencies and synergistic effect. Construction and Building Materials, 168, pp.622-632.

Moheseni, E., Tang, W. & Wang, S., 2019. Investigation of the Role of Nano-Titanium on Corrosion and Thermal Performance of Structural Concrete with Macro-Encapsulated PCM. molecules, 24(7), p. 1360.

Chithra, S., Kumar, S.S. and Chinnaraju, K., 2016. The effect of Colloidal Nano-silica on workability, mechanical and durability properties of High Performance Concrete with Copper slag as partial fine aggregate. Construction and Building Materials, 113, pp.794-804.

Sorathiya, J., Shah, S. and Kacha, S.M., 2017. Effect on addition of nano “titanium dioxide”(TiO2) on compressive strength of cementitious concrete. Kalpa Publications in Civil Engineering, 1, pp.219-225.